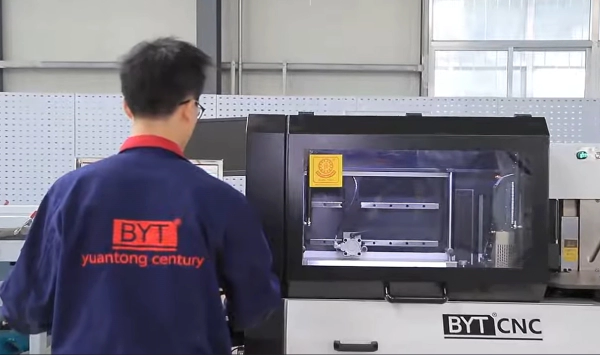

Why Choose a Channel Letter Bender from China? In today’s fast-paced signage industry, precision, efficiency, and cost-effectiveness are crucial when choosing equipment for fabricating channel letters. One of the most popular tools for this job is the channel letter bender, which helps create clean, consistent bends in metal for signage purposes. While there are numerous options available on the market, purchasing a channel letter bender from China can offer distinct advantages that can benefit businesses worldwide. 1. Cost-Effective Solutions One of the primary reasons businesses choose to purchase a channel letter bender from China is the cost savings. Manufacturing in China benefits from economies of scale, low labor costs, and advanced manufacturing technologies, allowing suppliers to offer high-quality machinery at a fraction of the price compared to local manufacturers in other countries. For companies that need reliable equipment without breaking the bank, Chinese-made channel letter benders are an excellent option. These machines offer competitive pricing without compromising on performance, making them ideal for small to medium-sized businesses or enterprises looking to streamline their production without overspending. 2. High-Quality Manufacturing Standards While China is often associated with cost savings, it is also home to numerous advanced manufacturing plants that meet international quality standards. Many Chinese manufacturers have invested heavily in cutting-edge technology, skilled labor, and quality control processes. These factors ensure that their channel letter benders perform consistently and meet the needs of customers in diverse industries. Whether you are working with aluminum, stainless steel, or other metals, Chinese manufacturers produce machines that are built to last. With features such as precise bending control, ease of use, and robust construction, a channel letter bender from China provides excellent value for your investment. 3. Innovative Features and Customization Chinese manufacturers are known for being at the forefront of technological innovation. As the demand for channel letter benders grows, so does the development of new and improved features. Many Chinese manufacturers offer machines equipped with the latest technologies, such as: Automatic and programmable functions that save time and reduce errors. Precise digital controls for accurate and consistent bends. Flexible bending options that can handle various metal thicknesses and sizes. Energy-efficient operations to reduce long-term operational costs. Additionally, Chinese manufacturers often provide options for customization, allowing businesses to tailor the channel letter bender to meet specific needs, whether it’s for a unique sign type or a specific metal bending requirement. 4. Strong Supplier Network and Customer Support When purchasing a channel letter bender from China, businesses gain access to a large, well-established supplier network. Chinese manufacturers have built strong reputations for providing exceptional customer service, with many offering: 24/7 customer support for troubleshooting and inquiries. Technical support for machine installation and maintenance. Comprehensive warranties and after-sales services to ensure continued operation and performance. Many suppliers also offer direct 1-on-1 engineer support, ensuring that customers have the assistance they need at every stage, from initial setup to ongoing machine care. 5. Global Shipping and Fast Delivery Chinese suppliers are known for their efficient and reliable global shipping capabilities. Regardless of your location, you can receive your channel letter bender in a timely manner. With increasingly streamlined shipping logistics and partnerships with global couriers, many manufacturers offer fast international delivery options to get your equipment up and running as quickly as possible. Furthermore, with the ability to ship worldwide, Chinese suppliers ensure that your equipment will be delivered directly to your door, minimizing the hassle of navigating local distribution channels or dealing with costly intermediaries. 6. Long-Term Cost Savings In addition to the upfront cost savings, purchasing a channel letter bender from China can lead to long-term cost reductions. The reliability, efficiency, and low maintenance costs associated with Chinese-made machines make them a sound investment for businesses. With advanced features designed to reduce operational costs, businesses can enjoy years of trouble-free performance, resulting in a lower total cost of ownership. 7. Reputation of Leading Brands Many well-established Chinese brands, such as BYTCNC, have earned global recognition for producing some of the best channel letter benders on the market. These brands not only provide excellent machinery but also ensure a high level of service and support, making them trustworthy options for businesses seeking reliable solutions. Conclusion: Choose a Channel Letter Bender from China for Superior Value Choosing a channel letter bender from China offers a unique combination of affordability, quality, innovation, and support that is hard to beat. Whether you’re looking to scale your operations, reduce costs, or improve production efficiency, Chinese-made channel letter benders are an excellent choice for businesses worldwide. With competitive pricing, advanced features, and reliable performance, these machines are the perfect investment for those looking to stay ahead in the fast-paced signage industry. For more information about channel letter benders, visit our website at BYTCNC for high-quality machines that suit your specific needs. https://youtu.be/1x90_0_7pS8?si=g_SmRvtxhvQmtuMA Learn more aboutBYT Channel Letter Bender Material width:10-220mm(0.4-8.6in) [Customizable]Thickness:Aluminum 0.3-2mm(.01-.079in) [Customizable]Stainless steel 0.3-1.5mm(.01-.059in). Certification:CE,ISO9001,FDAWarranty: 2 Years More Details

Máquina dobladora rápida de letras de canal

¿Qué tan rápido puede trabajar una máquina automática para letras de canal mejor que la mano de obra? https://youtu.be/1x90_0_7pS8?si=g_SmRvtxhvQmtuMA En el mundo de la fabricación de letreros, especialmente para letras de canal, la eficiencia y precisión son cruciales. Los métodos tradicionales de fabricación de letras de canal a menudo dependen en gran medida de la mano de obra, lo que puede ser un proceso largo y propenso a errores humanos. Sin embargo, con la llegada de las máquinas automáticas para letras de canal, los fabricantes ahora pueden optimizar sus operaciones, aumentar la producción y mejorar significativamente la calidad general de sus productos. Pero, ¿qué tan rápido puede trabajar una máquina automática para letras de canal, y cómo se compara con la mano de obra en términos de velocidad y eficiencia? Vamos a echar un vistazo más de cerca. ¿Qué es una máquina para letras de canal? Una máquina para letras de canal es un equipo automatizado diseñado para la producción de letras de canal: las letras tridimensionales típicamente utilizadas para señalización. Estas máquinas están equipadas con características avanzadas que les permiten realizar tareas como doblar, cortar, soldar y ensamblar letras de canal con alta precisión y velocidad. Las máquinas automáticas para doblar letras de canal son especialmente populares por su capacidad para doblar metal rápidamente en la forma deseada, lo que permite una producción rápida de los componentes del letrero. Comparación de velocidad: Máquinas automáticas para letras de canal vs. mano de obra 1. Tiempo de producción más rápido La mano de obra manual en la fabricación de letras de canal implica múltiples etapas, como cortar, doblar y soldar, lo que puede ser intensivo en mano de obra y llevar mucho tiempo. Por ejemplo, un trabajador puede tardar entre 30 minutos y una hora en doblar y dar forma al metal de una letra de manera manual. Si el proyecto involucra múltiples letras o diseños complejos, el tiempo total de producción puede aumentar rápidamente. En cambio, una máquina automática para letras de canal puede completar la misma tarea en una fracción del tiempo. Estas máquinas pueden doblar y dar forma al metal en solo unos minutos por letra, reduciendo significativamente el tiempo total dedicado al proyecto. Algunos modelos avanzados incluso pueden completar múltiples letras al mismo tiempo, aumentando la productividad y reduciendo el tiempo de espera entre etapas. 2. Velocidad y producción consistentes Otra ventaja de usar una máquina automática es su capacidad para mantener una velocidad constante durante todo el proceso de producción. La mano de obra manual puede verse influenciada por factores como la fatiga del trabajador, el nivel de habilidad y las distracciones, lo que puede llevar a fluctuaciones en la velocidad de producción. Sin embargo, una máquina puede trabajar continuamente a un ritmo constante sin necesidad de pausas, garantizando que cada letra se produzca a la misma velocidad y calidad. Para pedidos de gran volumen, esta consistencia es esencial. Mientras que la mano de obra manual puede requerir descansos, turnos y coordinación entre varios trabajadores, una máquina automática para letras de canal puede operar las 24 horas del día, aumentando la cantidad de letras de canal producidas por día sin sacrificar la calidad. 3. Tiempo de configuración reducido Configurar una estación de trabajo manual para letras de canal a menudo requiere ajustar equipos, reunir materiales y preparar cada paso del proceso de producción. Esto puede llevar una cantidad considerable de tiempo, especialmente cuando se trabaja en pedidos personalizados o de gran tamaño. Las máquinas automáticas para letras de canal, por otro lado, están diseñadas para ser fáciles de usar y requieren una configuración mínima. Muchas máquinas vienen con programas y configuraciones preestablecidas para diferentes estilos y tamaños de letras, lo que permite realizar ajustes rápidos entre trabajos. La máquina puede ser preprogramada con diseños específicos, reduciendo aún más la necesidad de intervención manual y el tiempo de configuración. Esto facilita y acelera la transición entre trabajos, mejorando aún más la eficiencia. 4. Minimización de errores y retrabajo Cuando se depende de la mano de obra manual, siempre existe el riesgo de error humano. Ya sea un cálculo incorrecto en las medidas, ángulos de doblado erróneos o soldaduras desiguales, estos errores pueden resultar en defectos que requieren retrabajo, lo que consume mucho tiempo. En algunos casos, puede ser necesario rehacer letras o incluso pedidos completos, lo que genera retrasos significativos en el proyecto. Las máquinas automáticas para letras de canal, sin embargo, están diseñadas para garantizar precisión. Con características como el doblado y corte controlados por computadora, estas máquinas minimizan las posibilidades de error. Cada letra se produce según las especificaciones exactas, reduciendo la necesidad de retrabajo y asegurando que el producto final cumpla con altos estándares de calidad. Esto no solo ahorra tiempo, sino que también reduce el desperdicio de materiales, lo que puede disminuir aún más los costos de producción. 5. Rentabilidad a largo plazo Aunque la inversión inicial en una máquina automática para letras de canal puede ser más alta que depender de la mano de obra manual, los ahorros a largo plazo en términos de tiempo, costos laborales y eficiencia son significativos. Las máquinas automáticas pueden operar con menos operadores, reduciendo la necesidad de grandes equipos. Esto también disminuye el costo general de mano de obra y permite a las empresas concentrar recursos en otras áreas del negocio, como marketing, ventas o atención al cliente. Además, dado que estas máquinas son más rápidas y precisas, el tiempo de entrega de los pedidos es mucho más corto, lo que permite a las empresas completar más trabajos en menos tiempo. Esta mayor producción se traduce en mayores ganancias con el tiempo, haciendo de las máquinas automáticas para letras de canal una inversión inteligente para las empresas de fabricación de letreros. Conclusión: ¿Por qué elegir una máquina automática para letras de canal? Cuando se compara la velocidad y eficiencia de las máquinas automáticas para letras de canal con la mano de obra manual, los beneficios son claros. Las máquinas automáticas pueden completar las tareas más

Por qué necesita una dobladora de letras de canal

¿Por qué necesitas una dobladora de letras de canal? Si eres fabricante de señales o trabajas en la industria de la cartelería, sabrás lo importante que es contar con herramientas y equipos de alta calidad que te ayuden a mejorar la productividad, reducir costos y ofrecer productos de excelente acabado. Una de las herramientas clave en la fabricación de letras de canal es la dobladora de letras de canal. En este artículo, exploraremos por qué una dobladora de letras de canal es esencial para tu negocio y cómo puede ayudarte a mejorar la eficiencia y calidad de tus productos. 1. Mayor Eficiencia y Ahorro de Tiempo La fabricación manual de letras de canal puede ser un proceso largo y tedioso, especialmente cuando se tienen que realizar muchas unidades en poco tiempo. Con una dobladora de letras de canal, puedes automatizar el proceso de doblado, lo que te permitirá producir más letras en menos tiempo. Esta eficiencia no solo reduce los plazos de entrega, sino que también te permite aceptar más pedidos, lo que puede traducirse en un crecimiento significativo para tu negocio. 2. Precisión y Calidad Consistente Una de las principales ventajas de utilizar una dobladora de letras de canal es la precisión que ofrece. El proceso manual a menudo depende de la destreza y experiencia del operario, lo que puede generar variaciones en el producto final. Con una dobladora automática, cada letra se fabrica con una precisión exacta, lo que garantiza la consistencia en todas las unidades producidas. Esto es fundamental para mantener la calidad del producto y satisfacer las expectativas de tus clientes. 3. Reducción de Costos Laborales El costo de la mano de obra es una de las mayores preocupaciones de cualquier negocio. Con una dobladora de letras de canal, puedes reducir la necesidad de mano de obra altamente calificada y, al mismo tiempo, mejorar la productividad. Estas máquinas son fáciles de operar y requieren menos personal para realizar el trabajo que de otro modo se realizaría manualmente. Al reducir los costos de mano de obra, puedes mejorar tus márgenes de ganancia y reinvertir en otras áreas de tu empresa. 4. Fabricación Personalizada y Versátil Las demandas de los clientes están cambiando, y cada vez más empresas buscan soluciones personalizadas para sus proyectos de señalización. Con una dobladora de letras de canal, puedes fabricar letras y signos con diferentes tamaños, formas y estilos, adaptándote a los requisitos específicos de cada cliente. Ya sea que necesites letras de canal grandes para una fachada comercial o letras más pequeñas para señalización interna, la máquina puede manejar todo tipo de proyectos, lo que te permite ampliar tu oferta de productos. 5. Mejora la Rentabilidad de Tu Negocio Una mayor eficiencia, menor tiempo de producción y menos costos laborales son algunos de los factores que contribuyen a una mayor rentabilidad. Al incorporar una dobladora de letras de canal en tu línea de producción, puedes reducir los costos operativos y, al mismo tiempo, aumentar la capacidad de producción. Esto te permitirá obtener más beneficios al ofrecer productos de alta calidad a precios competitivos. 6. Soporte y Asesoramiento Especializado Invertir en una máquina de doblado de letras de canal de calidad también significa contar con soporte técnico y asesoramiento especializado. En BYTCNC, ofrecemos soporte personalizado 24/7, lo que significa que siempre tendrás acceso a la ayuda que necesitas para mantener tus operaciones funcionando sin problemas. Nuestro equipo de ingenieros y expertos está disponible para ofrecerte asistencia en la instalación, operación y mantenimiento de tu máquina. Conclusión: ¡Impulsa Tu Negocio con una Dobladora de Letras de Canal! Si estás buscando mejorar la eficiencia, la calidad y la rentabilidad de tu negocio de fabricación de letras de canal, una dobladora de letras de canal es la herramienta esencial que necesitas. Con ella, podrás producir productos de alta calidad con mayor rapidez, reducir costos operativos y satisfacer las demandas personalizadas de tus clientes. Para obtener más información sobre nuestras dobladoras de letras de canal, visita nuestra página en español en bytcnc.us/dobladora-de-letras-de-canal y descubre cómo podemos ayudarte a llevar tu negocio al siguiente nivel. En BYTCNC, estamos comprometidos con ofrecerte equipos de alta calidad y el mejor soporte para ayudarte a crecer. ¡Contáctanos hoy mismo! https://youtu.be/1x90_0_7pS8?si=g_SmRvtxhvQmtuMA Learn more aboutBYT Channel Letter Bender Processing material width:10-160mmThickness:Aluminum 0.3-1.5mm,Stainless steel 0.3-1.2mm.Suitable for All kinds of material. More Details

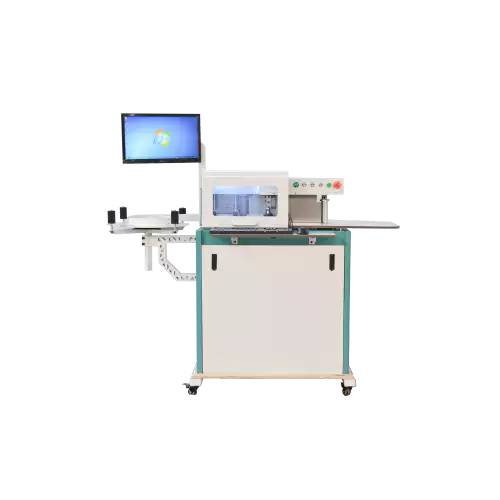

Economical Channel Letter Bending Machine: BWZ-F2

Economical Channel Letter Bending Machine: BWZ-F2 If you’re looking to enter the signage industry without breaking the bank, the BWZ-F2 Channel Letter Bending Machine is your perfect solution. This compact, precision-engineered machine offers outstanding value, making it ideal for entrepreneurs or small businesses starting with minimal investment. Learn more about this innovative device here. https://youtu.be/7ffynvs5Hks?si=bcG7nyaK7JHWV7YQ Why Choose the BWZ-F2 Channel Letter Bending Machine? Affordable Entry PointThe BWZ-F2 is designed to provide an economical solution for creating high-quality channel letters. With a low upfront cost, this machine enables you to kick-start your business without the need for heavy financial commitment. Compact and Space-SavingSpace constraints are no longer an issue. The BWZ-F2’s compact design ensures it fits comfortably even in smaller workshops. Whether you’re working from a dedicated factory or a home garage, this machine adapts to your environment seamlessly. High Precision with Encoder TechnologyEquipped with advanced encoder technology, the BWZ-F2 guarantees precise bending for every project. This feature minimizes material waste and ensures consistent quality, helping you deliver professional-grade channel letters to your customers. User-Friendly OperationSimplicity meets efficiency with the BWZ-F2. Its intuitive controls make it easy for beginners to operate, reducing the learning curve and enabling faster project turnarounds. Start Your Channel Letter Business Today The BWZ-F2 Channel Letter Bending Machine is the ultimate choice for anyone looking to produce custom channel letters with efficiency and precision. Whether you’re crafting letters for storefront signs, advertising boards, or illuminated signage, this machine offers the perfect balance of affordability, quality, and ease of use. Visit our website to learn more about the BWZ-F2 and explore how this compact, cost-effective solution can elevate your business: https://www.bytcnc.us/letter-bending-machine/. Learn more aboutBYT Channel Letter Bender Processing material width:10-160mmThickness:Aluminum 0.3-1.5mm,Stainless steel 0.3-1.2mm.Suitable for All kinds of material. More Details

How Sign Makers Can Expand Their Business

How Sign Makers Can Expand Their Business: The Advantages of Investing in an Automatic Channel Letter Bender In the sign-making industry, businesses are increasingly looking for innovative and efficient solutions to boost growth and productivity. As a sign maker, not only do you need to create eye-catching designs, but you also need to ensure that you can deliver high-quality products quickly. To stay competitive, investing in an automatic channel letter bender is a smart choice for expanding your business. This article will explore how this piece of equipment can streamline your sign-making process and drive business growth. 1. Automatic Channel Letter Bender: Saving Time and Boosting Efficiency Traditional channel letter bending often requires a lot of manual labor, which can be time-consuming and prone to errors. An automatic channel letter bender, on the other hand, can efficiently handle the bending process, significantly reducing production time. With high levels of automation and simple operation, this machine not only lowers labor costs but also boosts production efficiency. For sign makers, this means being able to take on more orders in less time, enabling scalable production and business expansion. 2. Improving Product Quality and Enhancing Customer Satisfaction As the demand for high-quality signs continues to rise, customers are becoming more discerning about precision and appearance. An automatic channel letter bender ensures that every product is consistent and precise, from the bending angle of the letters to their dimensions. This improves the overall product quality and helps sign makers build trust and satisfaction among clients. Higher quality products often lead to repeat business, positive word-of-mouth, and increased customer retention—key factors in driving business growth. 3. Reducing Dependence on Manual Labor and Lowering Labor Costs For many sign makers, hiring and training skilled workers can be a significant challenge. By introducing automated equipment, you can reduce reliance on highly skilled workers. The automatic channel letter bender is easy to operate, even for new employees, which means less time and money spent on training. This reduction in labor costs allows businesses to allocate resources more effectively and improve profitability. 4. Offering Customization to Meet Diverse Customer Needs As customer preferences become more varied, sign makers need to continuously innovate and offer more personalized services. An automatic channel letter bender can handle a wide range of materials and letter styles, making it easy to produce customized signs. Whether it’s for a small or large project, simple lettering or intricate designs, this machine can handle it all. This flexibility allows sign makers to cater to a broader range of clients, expanding their market reach and helping grow the business. 5. Increasing Production Capacity and Scaling Your Business With the addition of an automatic channel letter bender, sign makers can significantly increase their production capacity, completing more orders in less time. This not only boosts production efficiency but also speeds up delivery times, enabling businesses to meet tight deadlines and satisfy customers with quicker turnaround times. Furthermore, the machine’s reliability and performance allow sign makers to handle larger-scale production needs, making it easier to scale the business and take on bigger projects. 6. Attracting New Customers and Enhancing Market Competitiveness In a competitive market, staying ahead of the curve is essential. By investing in an automatic channel letter bender, you gain a technological edge that sets your business apart. Offering high-quality, fast, and customizable services will help attract new customers and outpace competitors. Additionally, the use of advanced equipment improves your brand image, showcasing your technical capabilities and innovative approach, which can further strengthen your position in the market. Conclusion: Expand Your Business with an Automatic Channel Letter Bender Whether it’s improving production efficiency, lowering costs, or enhancing customer satisfaction, an automatic channel letter bender is a powerful tool for expanding your sign-making business. By investing in this advanced equipment, you not only increase your company’s overall competitiveness but also position yourself to capture a larger market share and sustain growth. If you’re looking to stand out in the sign-making industry, the automatic channel letter bender is a key step toward success. For more information about BYT’s automatic channel letter bender or to get personalized support, visit our website or contact our customer service team. We’re here to help you take your sign-making business to the next level! https://youtu.be/wRJuGE8eu4I?si=xpZQhFRlXbFwk6X5 Learn more aboutBYT Channel Letter Bender Processing material width:10-160mmThickness:Aluminum 0.3-1.5mm,Stainless steel 0.3-1.2mm.Suitable for All kinds of material. More Details

Buy a Laser Welder Together with a Channel Letter Bender

Why You Need to Buy a Laser Welder Together with a Channel Letter Bender https://youtu.be/FkEzgCceZXw?si=9NH_xZfugTmtRW0G When working with stainless steel channel letters, owning both a channel letter bender and a laser welder is essential. While the bender shapes the sides of the letters, a laser welder is crucial for assembling them by welding the front face to the side. Without a welder, you simply can’t complete a stainless steel letter, as these materials require a precise, durable bond to maintain their form and withstand environmental factors. Let’s explore why a laser welder is a necessary companion to your channel letter bender and how it enhances your stainless steel letter-making process. 1. Essential for Completing Stainless Steel Channel Letters Stainless steel letters are in high demand for their durability and professional appearance. However, assembling these letters requires the front face and side to be securely welded together. A laser welder provides the precision and strength needed for this bond, making it indispensable for completing stainless steel channel letters. 2. Superior Welding Quality and Strength Laser welding offers smooth, strong joints that are visually flawless and durable enough for outdoor signage. This technology ensures a secure bond between the channel letter components, resulting in letters that can withstand wear and tear, weather, and time. By choosing a laser welder, you’re investing in a tool that enhances the overall durability and appearance of your signage. 3. Improved Production Speed and Efficiency Combining a channel letter bender with a laser welder streamlines your production process. After bending the sides, you can immediately weld the components together, reducing the need for additional manual assembly. This efficiency allows you to produce more letters in less time, helping to increase output and profitability. 4. Enhanced Precision and Minimal Distortion Laser welding’s precision minimizes heat distortion, a common issue when welding stainless steel. This ensures that your letters maintain their intended shape and don’t warp during the welding process. The ability to produce clean, precisely shaped letters makes laser welding ideal for producing premium-quality signage. 5. Cleaner Finish for Professional Results Stainless steel signage demands a professional, polished appearance. Laser welding produces minimal splatter and smoke, resulting in a cleaner workspace and reducing the need for extensive post-weld cleanup. This makes it ideal for achieving the smooth, seamless finish that clients expect from high-quality stainless steel letters. 6. Cost-Effective Investment with Long-Term Benefits While adding a laser welder to your channel letter production line involves an initial investment, the long-term benefits outweigh the costs. The precision and efficiency of a laser welder minimize material wastage and reduce the time spent on assembly, leading to cost savings over time. A laser welder quickly pays for itself by enabling you to produce durable, visually appealing channel letters efficiently. 7. Enhanced Capability for Custom and Complex Designs For custom projects or intricate designs, laser welding provides the flexibility to meet complex specifications without compromising quality. Its precision allows you to create unique stainless steel letters that align with specific design requirements, setting your shop apart by offering more options to clients. 8. Watch Our Laser Welder in Action Want to see our laser welder’s capabilities firsthand? Check out our demonstration video to understand how it seamlessly integrates with your channel letter production line, showing the accuracy and strength it brings to stainless steel channel letter assembly. Conclusion For shops specializing in stainless steel channel letters, a laser welder is a vital investment that completes the production process, providing the durability, precision, and professional finish clients demand. Pairing your channel letter bender with a laser welder allows you to create long-lasting, eye-catching stainless steel signage efficiently and cost-effectively. Visit bytcnc.us to explore our high-quality laser welders and channel letter benders and take your business to the next level. Learn more aboutBYT Channel Letter Bender Processing material width:10-160mmThickness:Aluminum 0.3-1.5mm,Stainless steel 0.3-1.2mm.Suitable for All kinds of material. More Details

How to Make Big Size Channel Letters

How to Make Big Size Channel Letters: Professional Tips and Tool Selection Big size channel letters are a powerful element in commercial signage, often seen on building facades, shopping malls, and other large commercial properties. Due to their significant size, these letters need to be not only visually appealing but also sturdy and durable. However, crafting large channel letters can be challenging, involving material handling, precision control, and maintaining consistency. Key Steps in Making Big Size Channel Letters Design and PlanningThe first step in creating large channel letters is design. Consider the size, material, font, and lighting arrangement during the design phase. A well-thought-out design ensures that the final product is both aesthetically pleasing and durable over time. Material SelectionLarge channel letters typically use aluminum, stainless steel, or other metals. These materials are chosen for their ability to withstand outdoor conditions while providing the necessary structural support. For outdoor signage, waterproof and corrosion-resistant materials are especially crucial. Cutting and BendingTurning your design into reality requires precise cutting and bending. During cutting, accuracy is essential to ensure the pieces fit together seamlessly during assembly. Bending, particularly with large letters, involves handling larger metal sheets, which can be challenging to do manually while maintaining precision and consistency. Assembly and FasteningAfter cutting and bending, the metal pieces are assembled into the final shape of the letters, using welding or other fastening methods. For large channel letters, ensuring each connection is secure is critical to prevent any loosening or damage during installation and use. Lighting InstallationIf the channel letters are to be illuminated, LED modules are typically used. Large letters require careful light placement to ensure even illumination, avoiding hot spots or uneven brightness across the letters. Methods to Improve Efficiency When making large channel letters, there are several tools and equipment options that can significantly improve efficiency and the quality of the final product. While manual work can accomplish much, modern technology can also play a key role, especially in large-scale or precision projects. CNC Cutting MachineA CNC cutting machine can ensure precise cuts, particularly with intricate or detailed designs. These machines can quickly and accurately produce the needed shapes, minimizing the risk of errors that might occur with manual cutting. Considering an Automatic Channel Letter BenderWhen it comes to bending metal for large letters, an automatic channel letter bender can significantly enhance efficiency. While manual bending is still common, an automatic bender provides more control over the bend’s angle and force, ensuring uniformity across all letters. For those looking to improve precision and reduce production time, incorporating such equipment into your workflow might be a worthwhile consideration. Specialized Assembly PlatformsTo maintain the flatness and consistency of each letter during assembly, using a specialized assembly platform can be beneficial. These platforms provide a stable working surface, reducing the risk of errors due to uneven or shaky surfaces. Conclusion Creating big size channel letters requires careful planning and collaboration across multiple stages. By focusing on design, selecting the right materials, and utilizing modern tools such as CNC cutting machines and automatic channel letter benders, you can ensure the quality and effectiveness of your final product. Each project comes with its unique demands, and combining traditional craftsmanship with modern equipment often leads to the best outcomes. If you’re seeking to enhance efficiency and precision in your production process, considering these tools could be a valuable step forward. Learn more aboutBYT Channel Letter Bender Processing material width:10-160mmThickness:Aluminum 0.3-1.5mm,Stainless steel 0.3-1.2mm.Suitable for All kinds of material. More Details

How to Save Money on Making Channel Letters

How to Save Money on Making Channel Letters In today’s competitive signage industry, finding ways to reduce costs without compromising quality is essential. Whether you’re a small shop or a large-scale producer, maximizing your budget can make a big difference in your profitability. In this article, we’ll start with some general money-saving tips for producing channel letters and then delve into how using an automatic channel letter bender can transform your operations and lead to even greater savings. General Money-Saving Tips for Channel Letter Production Before we dive into the specifics of automatic channel letter benders, let’s explore a few basic strategies that can help you save money across the board in channel letter production: Bulk Purchasing of Materials Why It Saves Money: Buying materials like aluminum, acrylic, and LED lights in bulk can significantly reduce your per-unit costs. Suppliers often offer discounts for large orders, which can translate into considerable savings, especially if you produce letters regularly. How to Implement: Plan your projects to anticipate material needs. Establish relationships with reliable suppliers who can offer bulk discounts. Streamline Your Design Process Why It Saves Money: The design phase can be time-consuming, and revisions add costs. Streamlining this process using design software that integrates directly with your production equipment can reduce errors and shorten production time. How to Implement: Invest in software that allows easy adjustments and quick conversion to production-ready files, reducing the need for multiple revisions. Optimize Material Usage Why It Saves Money: Wastage during cutting and bending can increase material costs. By optimizing how materials are cut and used, you can reduce scrap and make the most out of your purchases. How to Implement: Use design software to calculate the best layout for cutting materials, ensuring minimal waste. Invest in Energy-Efficient Equipment Why It Saves Money: Equipment that consumes less energy can significantly lower your utility bills, especially if you run a large operation. How to Implement: Research and choose machines that are energy-efficient and designed for long-term use. Look for equipment with Energy Star ratings or other energy efficiency certifications. Why an Automatic Channel Letter Bender is a Game-Changer After implementing the basic money-saving strategies, consider the impact of upgrading your equipment, particularly by using an automatic channel letter bender. Here’s how it can further enhance your cost-saving efforts: 1. Drastic Reduction in Manpower Costs One of the most significant expenses in channel letter production is labor. Manual processes require a skilled workforce, which can be expensive. Cost Savings: With an automatic channel letter bender, you can reduce the number of employees needed to operate the machinery. The machine handles cutting, bending, and shaping, tasks that would typically require multiple workers. This reduction in workforce needs can save you thousands in salaries, benefits, and overtime pay. Implementation: Shift your workforce from manual production to machine operation, focusing on training a smaller, highly skilled team to operate and maintain the bender. 2. Enhanced Production Efficiency Time is money, and the faster you can produce high-quality channel letters, the more projects you can take on. Cost Savings: An automatic channel letter bender speeds up production by automating repetitive tasks. It works faster than manual labor and can run continuously without breaks, reducing the time required to complete orders. This efficiency allows you to increase output without hiring additional staff. Implementation: Integrate the bender into your production line to handle large volumes of work with consistent quality, reducing lead times and increasing customer satisfaction. 3. Material Optimization and Waste Reduction Materials like aluminum and stainless steel are a significant cost in channel letter production. Any waste directly impacts your bottom line. Cost Savings: The precision of an automatic bender ensures that materials are cut and bent with minimal waste. Unlike manual methods, which can result in errors and wasted materials, the bender’s accuracy optimizes material usage, leading to lower material costs. Implementation: Use the bender’s software to plan cuts and bends meticulously, ensuring each piece of material is used to its fullest potential. 4. Lower Maintenance and Operational Costs Manual machines often require frequent maintenance, which can disrupt production and increase costs. Cost Savings: Automatic channel letter benders are designed for durability and typically have lower maintenance needs. This translates into fewer interruptions and reduced spending on repairs. Additionally, because these machines are more energy-efficient, you’ll also save on utility costs. Implementation: Schedule regular maintenance checks to keep the bender in optimal condition while enjoying reduced downtime compared to manual machines. 5. Flexibility and Versatility in Production Adapting to different customer needs can be challenging with manual equipment, which might not handle a wide range of materials or designs. Cost Savings: An automatic channel letter bender can work with various materials and create complex designs, eliminating the need for multiple machines or outsourcing. This flexibility allows you to take on diverse projects without additional investment in new equipment. Implementation: Train your team to utilize the bender for a range of projects, maximizing the return on your investment and reducing the need for extra tools or machines. Conclusion: Maximize Your Savings with Smart Investments While basic cost-saving measures can help you reduce expenses in channel letter production, the savings come from investing in advanced technology like an automatic channel letter bender. By cutting down on labor, improving efficiency, reducing waste, and lowering operational costs, this equipment pays for itself over time and helps your business stay competitive in a crowded market. Implement these strategies today to start seeing significant savings in your channel letter production process and consider the long-term benefits of upgrading to an automatic channel letter bender. Your bottom line will thank you! https://youtu.be/urnkSqNMPTI?si=1yEMUR1Cfa5cHtzG 25+ Yrs of Quality: BYT Channel Letter Benders Our 25+ years of experience ensure top-tier machines meeting strict European safety & performance standards (CE). Backed by continuous SGS certification, you’re guaranteed a reliable, long-lasting solution. 176 COUNTRIES EXPORTED 1996 FACTORY FOUND IN https://youtu.be/1Kyf1r5KLkI?si=W4V7Y8zANZC_3xhf Learn more aboutBYT Channel Letter Bender Processing material width:10-160mmThickness:Aluminum 0.3-1.5mm,Stainless steel 0.3-1.2mm.Suitable for All kinds of material. More Details OUR