Choose Aluminum or Stainless Steel Channel Letter Bender

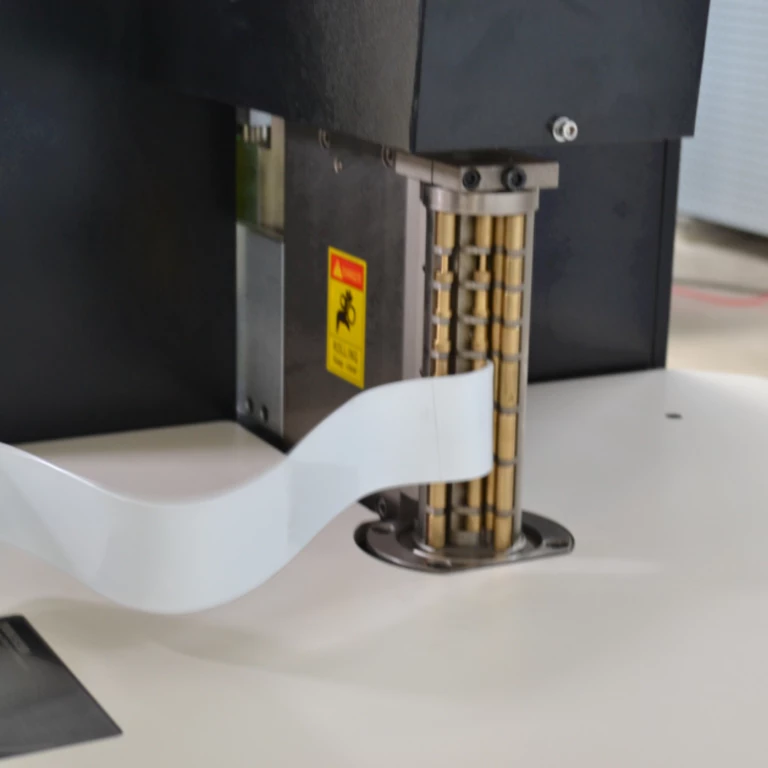

Aluminum vs. Stainless Steel Channel Letter Benders: Which material is Right for Your Sign? Introduction – Materials & Channel Letter Bender When creating eye-catching and durable channel letter signs, the choice of coil material is crucial. Two popular options are aluminum and stainless steel. Each material offers unique advantages and considerations. In this article, we’ll delve into the key differences between aluminum and stainless steel channel letter coils to help you make an informed decision for your signage project. Understanding Channel Letter Coils Before diving into the comparison, let’s briefly explain what channel letter coils are. They are pre-cut metal strips used to construct the sides of channel letters. These coils are bent into shape to form the letter’s structure, providing a clean, professional finish. Aluminum Channel Letter Coils Advantages: Lightweight: Easier to handle and install. Cost-effective: Generally more affordable than stainless steel. Versatility: Can be easily painted or powder coated for various color options. dmjdmetal.en.made-in-china.com Corrosion resistance: Suitable for most outdoor environments. Disadvantages: Less durable than stainless steel in harsh conditions. May dent or scratch more easily. Stainless Steel Channel Letter Coils Advantages: Durability: Highly resistant to corrosion, scratches, and dents. Longevity: Maintains its appearance for many years. High-end look: Provides a premium, modern aesthetic. Disadvantages: Heavier: Requires more robust installation methods. More expensive than aluminum. Limited color options: Typically requires painting or powder coating. Factors to Consider When Choosing To select the suitable material for your channel letter coils, consider the following factors: Budget: Aluminum is generally more budget-friendly, while stainless steel offers a higher price point. Environment: Stainless steel is ideal for harsh outdoor conditions, while aluminum is suitable for most environments. Aesthetics: Stainless steel provides a modern, upscale look, while aluminum offers more color and finish options. Durability: If longevity and resistance to damage are priorities, stainless steel is the better choice. Weight: Aluminum is lighter, making it easier to handle and install. Conclusion of choosing channel letter bender Both aluminum and stainless steel channel letter coils have their merits. The best choice depends on your specific project requirements and preferences. By carefully considering the factors outlined above, you can select the material that will create the perfect channel letter sign for your business. After knowing how to choose the material, you know how to choose the right machines. https://youtu.be/urnkSqNMPTI?si=nW1alKkKGXrok_4F 25+ Yrs of Quality: BYT Channel Letter Benders Our 25+ years of experience ensure top-tier machines meeting strict European safety & performance standards (CE). Backed by continuous SGS certification, you’re guaranteed a reliable, long-lasting solution. 176 COUNTRIES EXPORTED 1996 FACTORY FOUND IN https://youtu.be/1Kyf1r5KLkI?si=W4V7Y8zANZC_3xhf Comparison List Swipe left to get more ← FEATURES BWZ-C1 BWZ-A BWZ-B1 BWZ-F2 Can Do All Aluminum Stainless Steel Flat Aluminum Stainless Steel All Aluminum Flat Aluminum Material Thickness 0.3-1.5mm(.01-.059in) [Customizable] 0.3-2mm(.01-.079in) [Customizable] 0.3-1.5mm(.01-.059in) [Customizable] 0.3-0.8mm(.01-.031in) [No More Opt] Material Width 10-160mm(0.4-6.3in) [Customizable] 10-220mm(0.4-8.6in) [Customizable] 10-160mm(0.4-6.3in) [Customizable] 10-100mm(0.4-3.9in) [No More Opt] Double Bending System Yes No No No Air Requirement 0.7 MPa 0.7 MPa 0.7 MPa 0.7 MPa Warranty 2 Years 2 Years 2 Years 2 Years Certification CE; ISO9001; FDA CE; ISO9001; FDA CE; ISO9001; FDA CE; ISO9001; FDA Learn More→ Learn More→ Learn More→ Learn More→