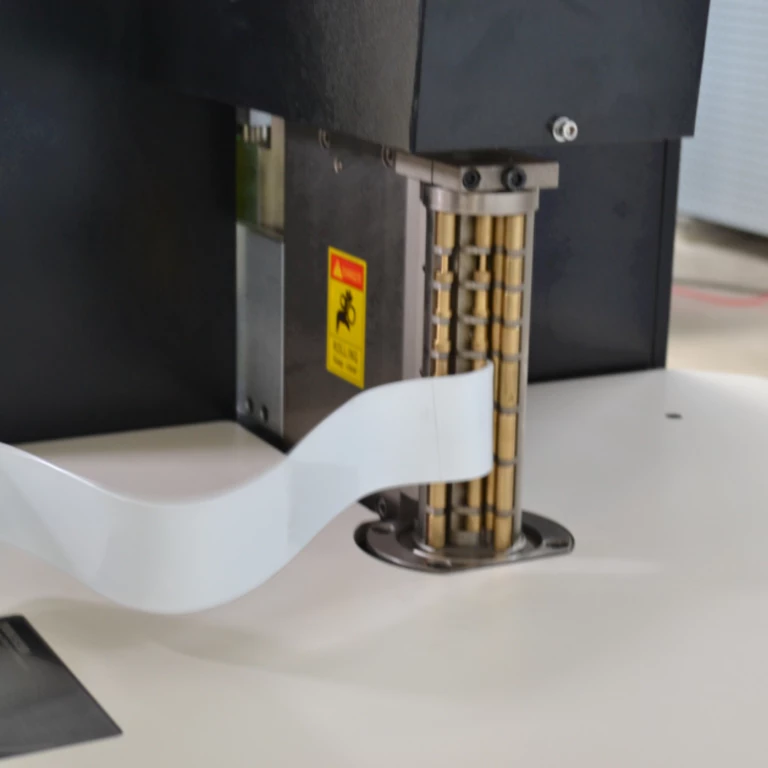

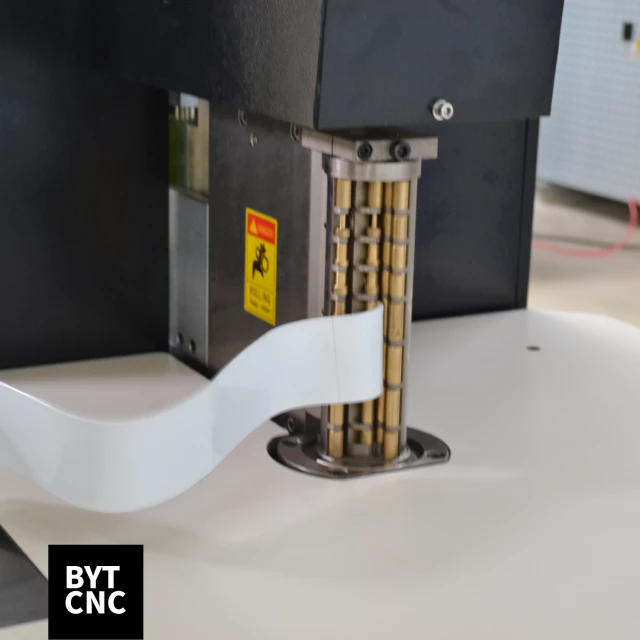

Why Choose BYTCNC’s Channel Letter Bender for Your Business In today’s competitive signage industry, efficiency, precision, and durability are essential for delivering high-quality results. For businesses that specialize in creating channel letters, investing in the right equipment is key to maintaining a competitive edge. BYTCNC’s Channel Letter Bender is the perfect solution for achieving consistent, professional results with every project. If you’re looking to enhance your production capabilities, here’s why BYTCNC’s Channel Letter Bender should be your top choice. https://youtu.be/vFCxnrPVSuA?si=cqVtGFwUtZdGrWQ1 1. Unmatched Precision and Accuracy When it comes to bending channel letters, precision is crucial. A slight error can affect the entire design, leading to wasted materials and costly repairs. BYTCNC’s Channel Letter Bender is designed to provide perfect bends every time. The machine’s advanced technology ensures that each bend is consistent, reducing the chances of human error and guaranteeing a high-quality finished product. With this machine, your team will experience seamless production with minimal adjustments needed. 2. Ease of Use Whether you’re a seasoned professional or new to the world of channel letter manufacturing, BYTCNC’s Channel Letter Bender is incredibly easy to use. The intuitive interface and user-friendly controls allow for quick setup and operation. The machine’s automatic features help streamline the bending process, saving time and effort. Plus, with a minimal learning curve, even new operators can quickly get up to speed and begin producing top-notch channel letters. 3. Durability for Long-Term Use When investing in machinery, it’s essential to choose products that will last. BYTCNC’s Channel Letter Bender is built with high-quality materials and superior craftsmanship, ensuring long-term durability. Whether you are working on small-scale projects or handling large orders, this machine can withstand continuous use without compromising performance. It’s a reliable addition to any workshop that guarantees years of service. 4. Efficient and Fast Production Time is money, especially in industries like signage, where fast turnaround times are critical to meeting customer demands. BYTCNC’s Channel Letter Bender is designed for speed without sacrificing quality. Its high bending capacity enables quick and efficient production, helping you meet tight deadlines and take on larger volumes of work without delay. With this machine, you’ll be able to maximize your shop’s efficiency and keep customers satisfied with fast delivery times. 5. Worldwide Shipping and 24/7 Customer Support BYTCNC is a trusted name in the manufacturing industry, offering global shipping on all its products. No matter where you are located, you can rely on timely delivery of your Channel Letter Bender. Additionally, BYTCNC offers 24/7 customer support and direct 1-on-1 engineering assistance. Whether you need help with installation, troubleshooting, or ongoing maintenance, our team is always ready to provide expert advice and assistance, ensuring your machine runs smoothly at all times. 6. Cost-Effective Investment When you invest in BYTCNC’s Channel Letter Bender, you’re not just purchasing a machine — you’re making a smart business decision. The machine offers excellent value for its price, combining precision, speed, and durability in a single package. With its low maintenance needs and ability to increase your production capabilities, the Channel Letter Bender delivers a strong return on investment. It helps you save time, reduce material waste, and ultimately boost your profit margins. 7. Worldwide Reputation and Trusted Quality BYTCNC has been a leader in the machine manufacturing industry since 1996, providing high-quality equipment to businesses worldwide. Our products, including the Channel Letter Bender, are trusted by companies of all sizes to deliver exceptional results. With a reputation for innovation and reliability, BYTCNC continues to provide cutting-edge solutions to the signage industry. 8. Customizable to Your Needs Every business has unique requirements. That’s why BYTCNC offers a customizable Channel Letter Bender that can be tailored to meet your specific needs. Whether you work with a variety of materials or require specific bending shapes, our machine can be adjusted to accommodate different styles and sizes. This flexibility ensures that you can handle a wide range of projects, giving you the versatility to serve a diverse customer base. Conclusion BYTCNC’s Channel Letter Bender offers a unique combination of precision, ease of use, durability, and speed that is perfect for businesses in the signage industry. With its efficient design, global support, and cost-effectiveness, it’s an investment that will elevate your production capabilities and help you stay ahead of the competition. Visit our product page here to learn more about how BYTCNC’s Channel Letter Bender can transform your business. Learn more aboutBYT Channel Letter Bender Processing material width:10-160mmThickness:Aluminum 0.3-1.5mm,Stainless steel 0.3-1.2mm.Suitable for All kinds of material. More Details

Why Channel Letter Benders Are Essential for Modern Signage Production

Why Channel Letter Benders Are Essential for Modern Signage Production In the fast-paced world of signage production, efficiency, precision, and versatility are key factors that determine a business’s success. Among the essential tools in a sign maker’s arsenal, channel letter benders stand out as indispensable machines that streamline the manufacturing process while enhancing product quality. At BYTCNC, we understand the vital role these machines play in modern signage production. Here’s why investing in a channel letter bender is crucial for your business. https://youtu.be/6SodzqhlQbI?si=kNBHGYYVEYIf2Hnz 1. Precision Engineering for Perfectly Shaped Letters Channel letter benders are designed to create precise bends in metal and plastic, ensuring that every letter is uniformly shaped and sized. This precision is vital for maintaining consistency across signage projects, which is essential for brand recognition. With a BYTCNC channel letter bender, you can produce accurate and high-quality letters that meet your clients’ expectations every time. 2. Increased Production Speed Time is money in the signage industry. Traditional manual bending methods can be labor-intensive and slow, leading to production delays. Channel letter benders automate this process, allowing sign makers to significantly reduce production time. With faster turnaround times, businesses can take on more projects and increase profitability. BYTCNC’s machines are engineered for high efficiency, helping you meet tight deadlines without compromising quality. 3. Versatility for Diverse Projects Modern signage production often requires a wide range of materials, including aluminum, acrylic, and other composites. Channel letter benders are versatile tools that can handle various thicknesses and types of materials. This flexibility allows sign makers to create customized solutions tailored to their clients’ specific needs. Whether it’s a bold outdoor sign or an intricate indoor display, a channel letter bender can accommodate diverse project requirements. 4. Reduced Labor Costs Investing in a channel letter bender can lead to significant labor cost savings. With the automation of the bending process, fewer workers are needed for manual labor, allowing your team to focus on more complex tasks that require creativity and skill. This not only improves overall efficiency but also helps you allocate resources more effectively. 5. Improved Safety Standards Safety is a critical concern in any manufacturing environment. Manual bending methods can pose risks, from repetitive strain injuries to accidents involving heavy materials. Channel letter benders minimize these risks by automating the bending process, leading to a safer workplace. BYTCNC machines are designed with user safety in mind, featuring protective mechanisms and easy-to-use controls. 6. Enhanced Aesthetic Appeal In signage, aesthetics matter. Channel letter benders ensure that letters have smooth, clean edges and consistent curves, enhancing the overall visual appeal of the signage. High-quality signage not only attracts customers but also reflects positively on your brand. With BYTCNC’s channel letter benders, you can achieve that professional look that sets your signage apart from the competition. 7. Reliable After-Sales Support At BYTCNC, we believe that our commitment to our customers goes beyond just selling machines. Our reliable after-sales support ensures that you have the assistance you need, from installation to maintenance. We provide comprehensive training and resources to help you get the most out of your channel letter bender, ensuring long-term success. Conclusion In the competitive landscape of modern signage production, having the right tools is essential for success. Channel letter benders from BYTCNC not only enhance precision and efficiency but also empower sign makers to take on a variety of projects with confidence. By investing in a channel letter bender, you’re not just purchasing a machine; you’re securing the future of your signage business. Explore our range of channel letter benders at bytcnc.us and discover how we can help you elevate your production capabilities. Learn more aboutBYT Channel Letter Bender Processing material width:10-160mmThickness:Aluminum 0.3-1.5mm,Stainless steel 0.3-1.2mm.Suitable for All kinds of material. More Details

Top 5 Benefits of Using a Channel Letter Bender for Your Signage Business

Top 5 Benefits of Using a Channel Letter Bender for Your Signage Business In the competitive world of signage, efficiency, precision, and quality are crucial to standing out. A key tool that has revolutionized the signage industry is the channel letter machine, particularly the channel letter bender. If you’re in the signage business and haven’t yet invested in a channel letter bender, you may be missing out on significant advantages that can elevate your business. In this article, we’ll explore the top 5 benefits of using a channel letter bender for your signage business. 1. Unmatched Precision and ConsistencyOne of the most significant benefits of using a channel letter bender is the precision it offers. Channel letters need to be uniform and exact to maintain the professional look that customers expect. A channel letter machine ensures that every bend, cut, and fold is precise, minimizing human error. This consistency not only enhances the quality of the signage but also ensures that each piece fits together perfectly, leading to a superior final product. 2. Increased Production SpeedIn the signage industry, time is money. The faster you can produce high-quality signs, the more projects you can take on, and the higher your profits. A channel letter bender significantly speeds up the production process. With automated bending, cutting, and folding, what once took hours can now be completed in minutes. This efficiency allows you to meet tight deadlines and handle larger volumes of work, giving your business a competitive edge. 3. Cost-EffectivenessInvesting in a channel letter machine can lead to significant cost savings over time. By automating the bending process, you reduce the need for manual labor, which lowers operational costs. Additionally, the precision of the machine minimizes material waste, as each letter is bent accurately to the required specifications. This reduction in waste not only saves money but also makes your operations more environmentally friendly. 4. Versatility in DesignChannel letter benders are incredibly versatile, allowing you to create a wide range of designs and styles. Whether you need to produce standard channel letters, reverse channel letters, or custom shapes, a channel letter machine can handle it all. This versatility enables you to offer more options to your clients, catering to diverse signage needs and increasing your marketability. With the ability to quickly switch between different styles, you can easily accommodate special requests and custom projects. 5. Improved Durability and QualityThe precision and consistency provided by a channel letter bender contribute to the durability of the finished product. Channel letters produced with a machine are more likely to have uniform bends and secure seams, which translates to a longer-lasting sign. High-quality signs lead to satisfied customers, repeat business, and a strong reputation in the market. By using a channel letter machine, you’re ensuring that your signs can withstand the elements and maintain their appearance over time. ConclusionIncorporating a channel letter bender into your signage business offers numerous benefits, from increased precision and production speed to cost savings and enhanced design versatility. By investing in this essential tool, you can produce higher-quality signs more efficiently, which can help you attract more clients and grow your business. As the signage industry continues to evolve, having the right equipment, like a channel letter machine, is crucial to staying competitive and delivering exceptional results. https://youtu.be/1x90_0_7pS8?si=g_SmRvtxhvQmtuMA Learn more aboutBYT Channel Letter Bender Processing material width:10-160mmThickness:Aluminum 0.3-1.5mm,Stainless steel 0.3-1.2mm.Suitable for All kinds of material. More Details

Introducción de la dobladora de letras de canal

La Dobladora de Letras Canal: Tu Aliada en la Fabricación de Señalización Introducción En el dinámico mundo de la publicidad y la señalización, las letras de canal destacan como elementos visuales impactantes. Para crear estas letras tridimensionales con precisión y eficiencia, la dobladora de letras de canal es una herramienta indispensable. En este artículo, exploraremos los beneficios y características clave de esta maquinaria especializada. ¿Qué es una Dobladora de Letras Canal? Una dobladora de letras canal es una máquina industrial diseñada específicamente para formar letras tridimensionales a partir de láminas planas de aluminio o acero inoxidable. Este proceso, conocido como doblado de canal, es fundamental en la fabricación de rótulos comerciales, letreros publicitarios y otros elementos de señalización. Beneficios de Utilizar una Dobladora de Letras Canal Aumento de la productividad: Las dobladoras de letras canal automatizan el proceso de fabricación, lo que resulta en una mayor producción y reducción de tiempos de entrega. Precisión y calidad: Estas máquinas garantizan una precisión excepcional en el doblado de las letras, lo que se traduce en un producto final de alta calidad y estéticamente atractivo. Versatilidad: Muchas dobladoras de letras canal ofrecen opciones de ajuste para adaptarse a diferentes tamaños y espesores de material, brindando flexibilidad en el diseño. Reducción de costos: Al optimizar el proceso de producción y minimizar el desperdicio de material, las dobladoras de letras canal contribuyen a reducir los costos operativos. Características Clave de una Dobladora de Letras Canal Capacidad de doblado: La máquina debe poder manejar diferentes espesores y anchos de material para adaptarse a diversos proyectos. Precisión: Es esencial que la dobladora ofrezca una alta precisión en el ángulo y forma de las curvas. Velocidad: Una velocidad de producción adecuada garantiza una eficiencia óptima. Durabilidad: La máquina debe estar construida con materiales resistentes para soportar el uso intensivo. Seguridad: Los sistemas de seguridad son fundamentales para proteger al operador. Aplicaciones de las Letras Canal Las letras de canal fabricadas con una dobladora de letras canal tienen una amplia gama de aplicaciones, incluyendo: Rótulos comerciales Letreros publicitarios Señalización de edificios Decoración interior y exterior Expositores y stands Conclusión La dobladora de letras canal es una inversión estratégica para cualquier empresa dedicada a la fabricación de señalización. Al incorporar esta tecnología avanzada, podrás mejorar la eficiencia, calidad y rentabilidad de tu negocio. https://youtu.be/urnkSqNMPTI?si=nW1alKkKGXrok_4F Comparison List Swipe left to get more ← FEATURES BWZ-C1 BWZ-A BWZ-B1 BWZ-F2 Can Do All Aluminum Stainless Steel Flat Aluminum Stainless Steel All Aluminum Flat Aluminum Material Thickness 0.3-1.5mm(.01-.059in) [Customizable] 0.3-2mm(.01-.079in) [Customizable] 0.3-1.5mm(.01-.059in) [Customizable] 0.3-0.8mm(.01-.031in) [No More Opt] Material Width 10-160mm(0.4-6.3in) [Customizable] 10-220mm(0.4-8.6in) [Customizable] 10-160mm(0.4-6.3in) [Customizable] 10-100mm(0.4-3.9in) [No More Opt] Double Bending System Yes No No No Air Requirement 0.7 MPa 0.7 MPa 0.7 MPa 0.7 MPa Warranty 2 Years 2 Years 2 Years 2 Years Certification CE; ISO9001; FDA CE; ISO9001; FDA CE; ISO9001; FDA CE; ISO9001; FDA Learn More→ Learn More→ Learn More→ Learn More→

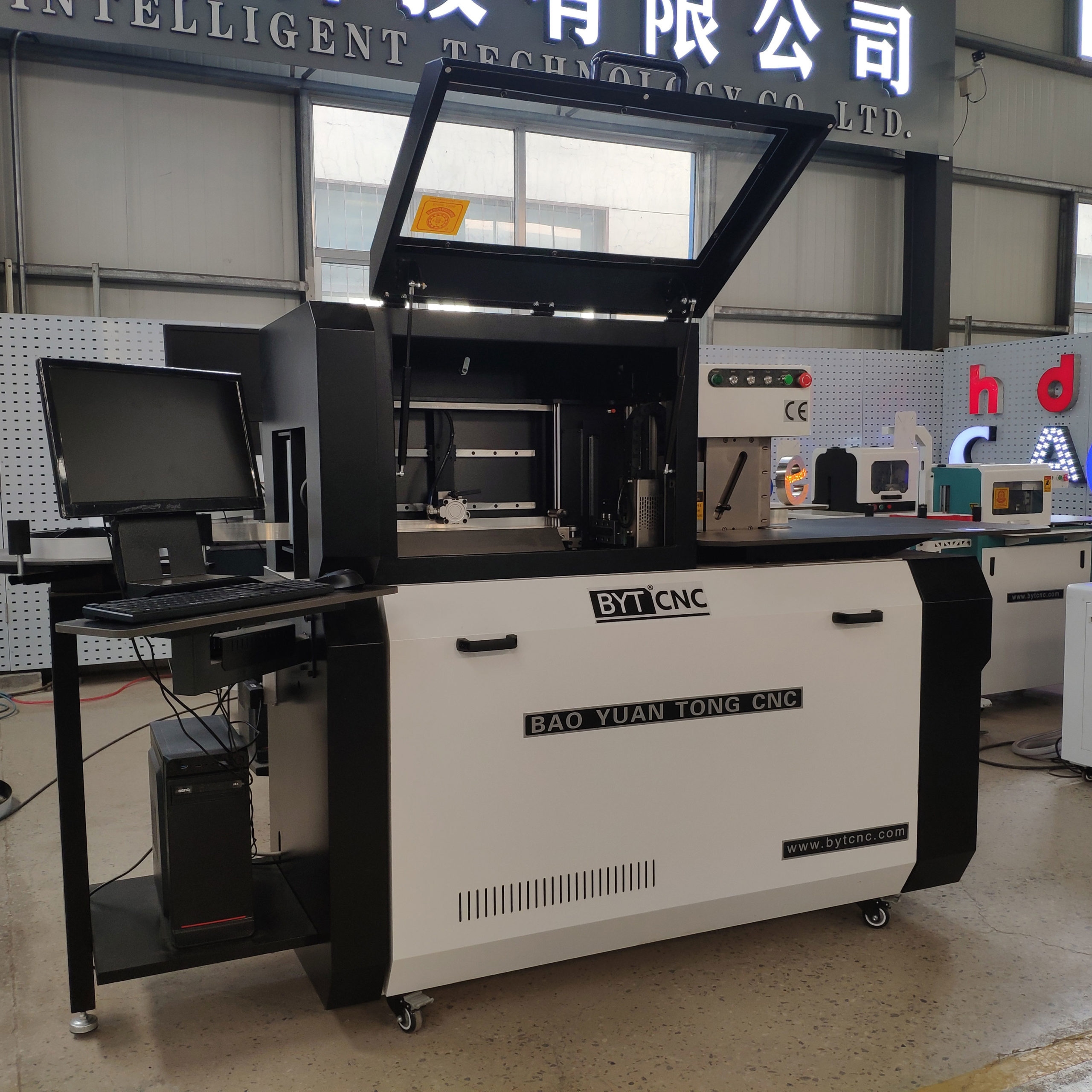

How To Use Channel Letter Bender BWZ-C1

SINCE 1996 CHANNEL LETTER BENDER FACTORY BYT® was founded in 1996, is a leading and trusted brand in channel letter bender area, serves clients in 176 countries. Channel Letter Bender Intro How To Use Channel Letter Bender C1 Steps of How To Make Channel Letters by BWZ-C1 01 Prepare Digital Files From Software Draw what you need in it Use Illustrator or Coreldraw to draw lines for the letters/signs. Save as .ai or .plt format. Our Engineer can help you learn the software. 02 Use Our ADT System to Work System of our channel letter bender Use ADT system for fast and accurate channel letter creation. Our Engineer will assist you in using this machine. Go Check our Bender→ 03 Channel Letter Bending Machine Working Alu/SS Letter bending machine Use letter bender to make channel letter side. Our Engineer will assist you in using this machine hand-in-hand. https://youtu.be/8z41BmQej8w?si=lIXoVKoHjw0CFe4X 04 Finish and Assamble Channel Letter Assemble Channel Letter then finish. If you choose aluminum side and plastic face, you need glue to make them together. If you choose stainless steel side and stainless steel face, you need to weld them together. Channel Letters From Our Clients 25+ Yrs of Quality: BYT Channel Letter Benders Our 25+ years of experience ensure top-tier machines meeting strict European safety & performance standards (CE). Backed by continuous SGS certification, you’re guaranteed a reliable, long-lasting solution. 176 COUNTRIES EXPORTED 1996 FACTORY FOUND IN https://youtu.be/1Kyf1r5KLkI?si=W4V7Y8zANZC_3xhf Comparison List Swipe left to get more ← FEATURES BWZ-C1 BWZ-A BWZ-B1 BWZ-F2 Can Do All Aluminum Stainless Steel Flat Aluminum Stainless Steel All Aluminum Flat Aluminum Material Thickness 0.3-1.5mm(.01-.059in) [Customizable] 0.3-2mm(.01-.079in) [Customizable] 0.3-1.5mm(.01-.059in) [Customizable] 0.3-0.8mm(.01-.031in) [No More Opt] Material Width 10-160mm(0.4-6.3in) [Customizable] 10-220mm(0.4-8.6in) [Customizable] 10-160mm(0.4-6.3in) [Customizable] 10-100mm(0.4-3.9in) [No More Opt] Double Bending System Yes No No No Air Requirement 0.7 MPa 0.7 MPa 0.7 MPa 0.7 MPa Warranty 2 Years 2 Years 2 Years 2 Years Certification CE; ISO9001; FDA CE; ISO9001; FDA CE; ISO9001; FDA CE; ISO9001; FDA Learn More→ Learn More→ Learn More→ Learn More→ Contact BYTCNC Contact us 请在浏览器中启用JavaScript来完成此表单。请在浏览器中启用JavaScript来完成此表单。Company NameWhatsApp *Email Address * Product You Need * CNC Router Channel Letter Bender Vacuum Former Laser Welder Channel Letter Coil Others Message Submit

What is Vacuum Forming Machine

Vacuum Forming Machine: A Comprehensive Guide https://youtu.be/dNm5XPB1qeA?si=QzGcyRI2nHGqbGy8 Vacuum forming machines, also known as thermoforming machines, are versatile pieces of equipment that utilize heat and pressure to mold plastic sheets into various shapes. These machines are widely employed in a diverse range of industries, including packaging, food and beverage, electronics, and medical devices. The Process of Vacuum Forming The vacuum forming process involves several key steps: Sheet Heating: Plastic sheets, typically made from thermoplastics like PET, PVC, or HIPS, are fed into the machine and heated to a pliable state using various heating methods, such as electric resistance heaters, gas flames, or infrared lamps. Drape and Molding: The softened plastic sheet is then draped over a forming mold, which is the shape the final product will take. Vacuum Application: A vacuum is applied to the space between the mold and the plastic sheet, drawing the softened plastic tightly against the mold’s contours. Cooling and Ejection: Once the plastic has conformed to the mold, it is cooled, typically using fans or chilled water, to solidify the shape. The finished product is then ejected from the mold. Types of Vacuum Forming Machines Vacuum forming machines come in various configurations to suit different production needs and product designs. Common types include: Semi-automatic Vacuum Forming Machines: These machines require manual intervention for loading and unloading parts, making them suitable for low-volume production runs. Automatic Vacuum Forming Machines: These machines automate the loading, unloading, and trimming processes, offering higher production rates and reduced labor costs. Pressure Forming Machines: These machines utilize compressed air instead of vacuum pressure to force the plastic sheet against the mold, ideal for thicker and more rigid materials. Applications of Vacuum Forming Machines Vacuum forming machines are employed in a wide spectrum of industries for producing a vast array of products, including: Packaging: Trays, blisters, clamshells, and other packaging solutions for food, beverages, consumer goods, and medical products. Food and Beverage: Cups, lids, containers, and other food-grade packaging items. Electronics: Protective covers, housings, and components for electronic devices. Medical Devices: Trays, enclosures, and disposable medical components. Automotive: Interior trim panels, light covers, and other automotive parts. Toys and Games: Action figures, packaging, and various toy components. Benefits of Using Vacuum Forming Machines Vacuum forming machines offer several advantages over other plastic forming methods: Versatility: They can produce a wide range of shapes and sizes from various thermoplastic materials. Cost-effectiveness: They are relatively inexpensive compared to other forming methods, making them suitable for both small and large production runs. Design Flexibility: They can incorporate intricate designs, textures, and undercuts into the molded products. Thin-walled Products: They can produce thin-walled parts with excellent strength-to-weight ratios. Material Efficiency: They minimize material waste during the forming process. Factors to Consider When Choosing a Vacuum Forming Machine Several factors should be considered when selecting a vacuum forming machine: Production Volume: The machine’s production capacity should match the anticipated production volume. Product Size and Complexity: The machine’s forming area and capabilities should accommodate the size and complexity of the desired products. Material Compatibility: The machine should be compatible with the types of thermoplastics to be used. Automation Level: The level of automation required for loading, unloading, and trimming should be considered. Budget: The cost of the machine and associated tooling should align with the budget. Conclusion Vacuum forming machines play a crucial role in various industries, offering a versatile, cost-effective, and efficient method for producing a diverse range of plastic products. With their ability to create complex shapes, thin-walled parts, and intricate designs, vacuum forming machines continue to be a valuable asset in the manufacturing landscape. 25+ Yrs of Quality: BYT Channel Letter Benders Our 25+ years of experience ensure top-tier machines meeting strict European safety & performance standards (CE). Backed by continuous SGS certification, you’re guaranteed a reliable, long-lasting solution. 176 COUNTRIES EXPORTED 1996 FACTORY FOUND IN https://youtu.be/1Kyf1r5KLkI?si=W4V7Y8zANZC_3xhf Our Vacuum Forming Machines BSX-Small Size From 600mm-900mmAll Customizable More Details BSX-Series Size From 900mm-3000mmAll Customizable More Details

How To Choose CNC Router

How To Choose CNC Router Choosing a CNC router can feel overwhelming. With a vast array of features and technical jargon, where do you even begin? Fear not, aspiring woodworker or maker! This guide will equip you with the knowledge to select the perfect CNC router for your needs. Know Your Project Scope: Material: Will you be working with wood, foam, or sturdier materials like stone? Spindle power (motor strength) should correspond to material hardness. Size: Consider the dimensions of your typical projects. A machine with a larger work area might be tempting, but a smaller footprint might be more practical for your workspace. Precision Matters: Drive System: Rack and pinion drives are affordable but less precise for intricate work. Ball screws offer superior accuracy but come at a higher cost. Lead screws find a balance between the two. User-Friendly Features: Software Compatibility: Does the machine work with your preferred design software? Seamless integration will streamline your workflow. Ease of Use: If you’re new to CNC, consider a machine with a user-friendly interface and readily available tutorials. Beyond the Basics: Customer Reviews: Read online reviews and forum discussions to glean insights on real-world performance and customer support. Build Quality: A sturdy machine with quality components ensures long-lasting performance and minimizes maintenance headaches. By carefully considering these factors, you’ll be well on your way to selecting the ideal CNC router. Remember, the “best” machine depends on your unique requirements. With the right research, you’ll be creating intricate masterpieces in no time! 25+ Yrs of Quality: BYT Channel Letter Benders Our 25+ years of experience ensure top-tier machines meeting strict European safety & performance standards (CE). Backed by continuous SGS certification, you’re guaranteed a reliable, long-lasting solution. 176 COUNTRIES EXPORTED 1996 FACTORY FOUND IN https://youtu.be/1Kyf1r5KLkI?si=W4V7Y8zANZC_3xhf Learn more aboutBYT Channel Letter Bender Processing material width:10-160mmThickness:Aluminum 0.3-1.5mm,Stainless steel 0.3-1.2mm.Suitable for All kinds of material. More Details OUR PRODUCTS Channel letter bender BWZ-A Channel letter bender BWZ-C1 Channel letter bender BWZ-B1 Channel letter bender BWZ-F2 Laser welder BHJ Channel letter coil SITE LINK HomePage Videos of Products Products List Contact About Us Privacy Policy Shipping & Return SITE INFO Sign Machine Manufacturer Since 1996@ BYTCNC Email: [email protected]: +86 193 5320 6091WeChat: +86 193 5320 6091More Contacts

how to choose channel letter bending machine

Bend Like a Pro: Choosing the Right Channel Letter Bending Machine for Your Business In the world of signage, channel letters reign supreme. Offering a sleek, professional look, they’re a popular choice for businesses of all sizes. But crafting these dimensional beauties requires the right tools, and a channel letter bending machine (also known as an automatic letter bender) is a game-changer. However, with a variety of options on the market, selecting the perfect machine can feel overwhelming. Fear not, signage superhero! This guide will equip you with the knowledge to bend with confidence, helping you choose the ideal channel letter bending machine for your business. Factors to Consider When Choosing a Channel Letter Bending Machine: Production Volume: Are you a high-volume sign maker churning out projects daily, or a smaller shop with occasional channel letter needs? A high-speed, automatic machine might be ideal for the former, while a more basic model could suffice for the latter. Consider your current and projected workload to ensure the machine meets your production demands. Material Compatibility: Not all channel letter bending machines are created equal. Make sure the machine you choose can handle the materials you typically use, such as aluminum, stainless steel, or even pre-painted metals. Thickness is also a factor; some machines have limitations on the maximum thickness they can bend. Letter Size and Complexity: The types of signs you create will influence your machine needs. Do you specialize in large, complex letters with tight bends? A machine with superior bending force and a wider range of bending radii might be necessary. Conversely, if you primarily work with simpler, smaller letters, a more basic model might be suitable. Ease of Use and Operator Training: Complexity isn’t just about the letters themself. Consider your team’s skillset. If you have experienced operators, a feature-rich machine might be a great fit. However, if your team is new to channel letter bending, a user-friendly machine with comprehensive training options from the supplier is crucial. Precision and Repeatability: Professional signage demands consistency. Look for a machine that delivers precise bends with minimal deviation, ensuring your letters look sharp and uniform. Machines with digital controls and memory functions can further enhance precision and repeatability. Budget and Return on Investment (ROI): Channel letter bending machines are an investment. While a top-of-the-line model might boast impressive features, consider your budget and realistically assess how quickly you’ll see a return on that investment. Beyond the Basics: Reliability and Durability: Look for a machine built with high-quality components and a reputation for lasting performance. This minimizes downtime and ensures your machine bends for years to come. Customer Service and Support: Even the best machines require occasional maintenance or troubleshooting. Choose a supplier that offers reliable customer service and readily available technical support. By carefully considering these factors, you’ll be well on your way to selecting the perfect channel letter bending machine for your business. Remember, the ideal machine is an extension of your craftsmanship, allowing you to bend with confidence and create stunning signage that sets your business apart. https://youtu.be/urnkSqNMPTI?si=1yEMUR1Cfa5cHtzG 25+ Yrs of Quality: BYT Channel Letter Benders Our 25+ years of experience ensure top-tier machines meeting strict European safety & performance standards (CE). Backed by continuous SGS certification, you’re guaranteed a reliable, long-lasting solution. 176 COUNTRIES EXPORTED 1996 FACTORY FOUND IN https://youtu.be/1Kyf1r5KLkI?si=W4V7Y8zANZC_3xhf Learn more aboutBYT Channel Letter Bender Processing material width:10-160mmThickness:Aluminum 0.3-1.5mm,Stainless steel 0.3-1.2mm.Suitable for All kinds of material. More Details OUR PRODUCTS Channel letter bender BWZ-A Channel letter bender BWZ-C1 Channel letter bender BWZ-B1 Channel letter bender BWZ-F2 Laser welder BHJ Channel letter coil SITE LINK HomePage Videos of Products Products List Contact About Us Privacy Policy Shipping & Return SITE INFO Sign Machine Manufacturer Since 1996@ BYTCNC Email: [email protected]: +86 193 5320 6091WeChat: +86 193 5320 6091More Contacts

What is Automatic Letter Bender

Automating Efficiency: The Rise of Automatic Channel Letter Machines In the fast-paced world of sign making, keeping up with demand and precision can be a challenge. Enter the automatic channel letter machine, a technological marvel that’s transforming the industry. Bytcnc.us, a leading provider of sign-making equipment, recognizes this shift and offers a variety of these machines to meet your needs. What are Channel Letters? Channel letters are three-dimensional signs with metal returns (sides) that hold a plastic face. These faces can be illuminated from behind (face-lit) or from the edges (halo-lit) to create a visually striking and professional sign. Why Use an Automatic Channel Letter Machine? Traditional channel letter fabrication involves manual bending, cutting, and assembly – a time-consuming and labor-intensive process. Automatic channel letter machines streamline this process by: Increased Speed: Machines can bend and form letters much faster than manual methods, significantly boosting production capacity. Enhanced Precision: CNC (Computer Numerical Control) technology ensures consistent and accurate bends, eliminating human error. Reduced Labor Costs: Automation minimizes the need for manual labor, allowing sign makers to focus on design and installation. Material Versatility: Many machines can handle various materials, including aluminum, stainless steel, and even specialty trims. Automatic Feed: Machines can load and unload channel letter returns, further reducing manual intervention. Integrated Punching: Certain models can automatically punch holes for rivets or screws, saving even more time. Software Compatibility: Advanced machines can directly import design files (DXF) for seamless production. Choosing the Right Automatic Channel Letter Machine With various options available, selecting the right machine depends on your specific needs. Here are some factors to consider: Production Volume: If you handle high volumes of signs, a high-speed machine is essential. Letter Size and Complexity: Machines have limitations on letter size and how intricate bends they can handle. Material Compatibility: Ensure the machine works with the materials you typically use. Budget: Automatic channel letter machines are an investment, so consider your budget and return on investment. BYTCNC offers a variety of machines to suit different needs and budgets. Their website likely allows you to browse their selection and find detailed specifications for each model. The Future of Channel Letter Signs Automatic channel letter machines represent a significant advancement in sign making. By incorporating automation and precision, these machines empower sign makers to produce high-quality signs faster and more efficiently. As technology continues to evolve, we can expect even more innovative features and capabilities to emerge in the future of automatic channel letter machines. https://youtu.be/urnkSqNMPTI?si=1yEMUR1Cfa5cHtzG Learn more aboutBYT Channel Letter Bender Processing material width:10-160mmThickness:Aluminum 0.3-1.5mm,Stainless steel 0.3-1.2mm.Suitable for All kinds of material. More Details OUR PRODUCTS Channel letter bender BWZ-A Channel letter bender BWZ-C1 Channel letter bender BWZ-B1 Channel letter bender BWZ-F2 Laser welder BHJ Channel letter coil SITE LINK HomePage Videos of Products Products List Contact About Us Privacy Policy Shipping & Return SITE INFO Sign Machine Manufacturer Since 1996@ BYTCNC Email: [email protected]: +86 193 5320 6091WeChat: +86 193 5320 6091More Contacts

CNC Channel Letter Bender: The Ultimate Guide

CNC channel letter benders are a valuable tool for any signmaker who wants to create high-quality, accurate channel letters.