Why You Need to Buy a Laser Welder Together with a Channel Letter Bender

When working with stainless steel channel letters, owning both a channel letter bender and a laser welder is essential. While the bender shapes the sides of the letters, a laser welder is crucial for assembling them by welding the front face to the side. Without a welder, you simply can’t complete a stainless steel letter, as these materials require a precise, durable bond to maintain their form and withstand environmental factors. Let’s explore why a laser welder is a necessary companion to your channel letter bender and how it enhances your stainless steel letter-making process.

1. Essential for Completing Stainless Steel Channel Letters

Stainless steel letters are in high demand for their durability and professional appearance. However, assembling these letters requires the front face and side to be securely welded together. A laser welder provides the precision and strength needed for this bond, making it indispensable for completing stainless steel channel letters.

2. Superior Welding Quality and Strength

Laser welding offers smooth, strong joints that are visually flawless and durable enough for outdoor signage. This technology ensures a secure bond between the channel letter components, resulting in letters that can withstand wear and tear, weather, and time. By choosing a laser welder, you’re investing in a tool that enhances the overall durability and appearance of your signage.

3. Improved Production Speed and Efficiency

Combining a channel letter bender with a laser welder streamlines your production process. After bending the sides, you can immediately weld the components together, reducing the need for additional manual assembly. This efficiency allows you to produce more letters in less time, helping to increase output and profitability.

4. Enhanced Precision and Minimal Distortion

Laser welding’s precision minimizes heat distortion, a common issue when welding stainless steel. This ensures that your letters maintain their intended shape and don’t warp during the welding process. The ability to produce clean, precisely shaped letters makes laser welding ideal for producing premium-quality signage.

5. Cleaner Finish for Professional Results

Stainless steel signage demands a professional, polished appearance. Laser welding produces minimal splatter and smoke, resulting in a cleaner workspace and reducing the need for extensive post-weld cleanup. This makes it ideal for achieving the smooth, seamless finish that clients expect from high-quality stainless steel letters.

6. Cost-Effective Investment with Long-Term Benefits

While adding a laser welder to your channel letter production line involves an initial investment, the long-term benefits outweigh the costs. The precision and efficiency of a laser welder minimize material wastage and reduce the time spent on assembly, leading to cost savings over time. A laser welder quickly pays for itself by enabling you to produce durable, visually appealing channel letters efficiently.

7. Enhanced Capability for Custom and Complex Designs

For custom projects or intricate designs, laser welding provides the flexibility to meet complex specifications without compromising quality. Its precision allows you to create unique stainless steel letters that align with specific design requirements, setting your shop apart by offering more options to clients.

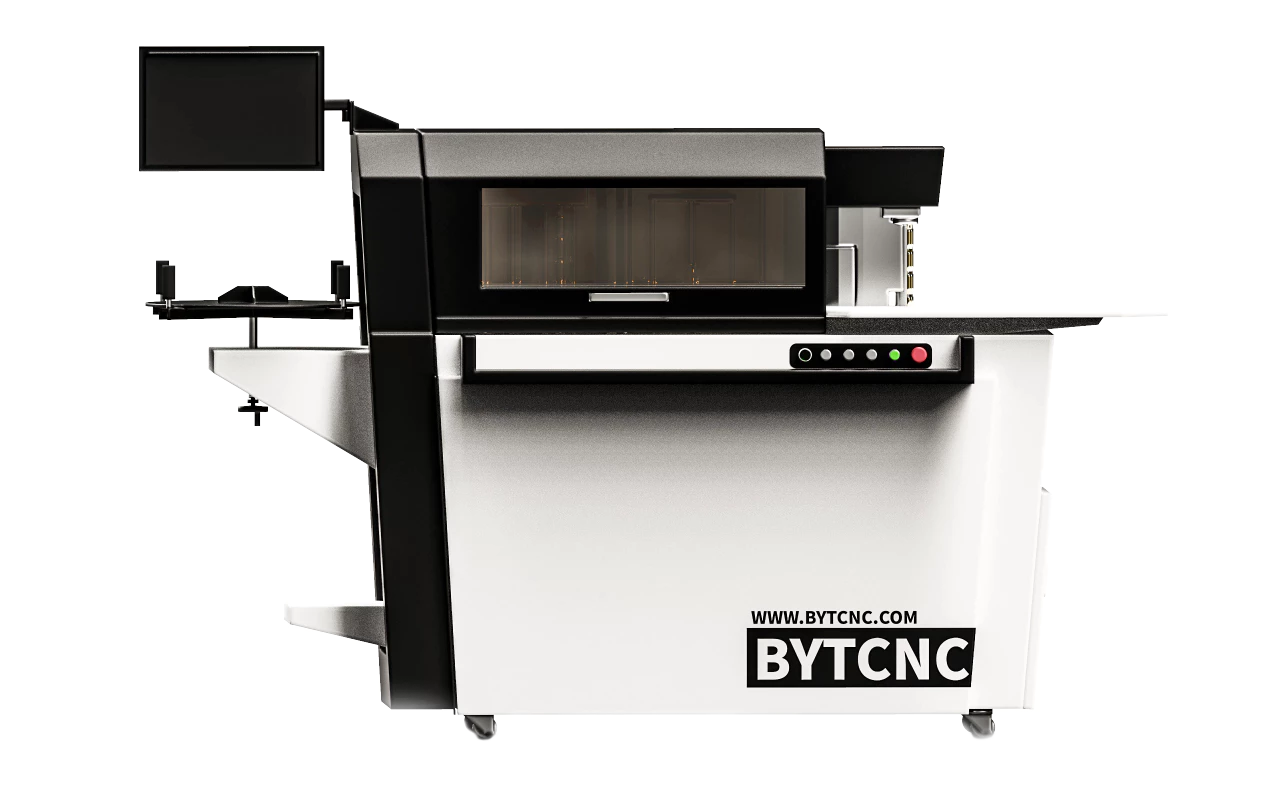

8. Watch Our Laser Welder in Action

Want to see our laser welder’s capabilities firsthand? Check out our demonstration video to understand how it seamlessly integrates with your channel letter production line, showing the accuracy and strength it brings to stainless steel channel letter assembly.

Conclusion

For shops specializing in stainless steel channel letters, a laser welder is a vital investment that completes the production process, providing the durability, precision, and professional finish clients demand. Pairing your channel letter bender with a laser welder allows you to create long-lasting, eye-catching stainless steel signage efficiently and cost-effectively. Visit bytcnc.us to explore our high-quality laser welders and channel letter benders and take your business to the next level.

Learn more about

BYT Channel Letter Bender

Processing material width:10-160mm

Thickness:

Aluminum 0.3-1.5mm,

Stainless steel 0.3-1.2mm.

Suitable for All kinds of material.