How to Make Big Size Channel Letters: Professional Tips and Tool Selection

Big size channel letters are a powerful element in commercial signage, often seen on building facades, shopping malls, and other large commercial properties. Due to their significant size, these letters need to be not only visually appealing but also sturdy and durable. However, crafting large channel letters can be challenging, involving material handling, precision control, and maintaining consistency.

Key Steps in Making Big Size Channel Letters

Design and Planning

The first step in creating large channel letters is design. Consider the size, material, font, and lighting arrangement during the design phase. A well-thought-out design ensures that the final product is both aesthetically pleasing and durable over time.Material Selection

Large channel letters typically use aluminum, stainless steel, or other metals. These materials are chosen for their ability to withstand outdoor conditions while providing the necessary structural support. For outdoor signage, waterproof and corrosion-resistant materials are especially crucial.Cutting and Bending

Turning your design into reality requires precise cutting and bending. During cutting, accuracy is essential to ensure the pieces fit together seamlessly during assembly. Bending, particularly with large letters, involves handling larger metal sheets, which can be challenging to do manually while maintaining precision and consistency.Assembly and Fastening

After cutting and bending, the metal pieces are assembled into the final shape of the letters, using welding or other fastening methods. For large channel letters, ensuring each connection is secure is critical to prevent any loosening or damage during installation and use.Lighting Installation

If the channel letters are to be illuminated, LED modules are typically used. Large letters require careful light placement to ensure even illumination, avoiding hot spots or uneven brightness across the letters.

Methods to Improve Efficiency

When making large channel letters, there are several tools and equipment options that can significantly improve efficiency and the quality of the final product. While manual work can accomplish much, modern technology can also play a key role, especially in large-scale or precision projects.

CNC Cutting Machine

A CNC cutting machine can ensure precise cuts, particularly with intricate or detailed designs. These machines can quickly and accurately produce the needed shapes, minimizing the risk of errors that might occur with manual cutting.Considering an Automatic Channel Letter Bender

When it comes to bending metal for large letters, an automatic channel letter bender can significantly enhance efficiency. While manual bending is still common, an automatic bender provides more control over the bend’s angle and force, ensuring uniformity across all letters. For those looking to improve precision and reduce production time, incorporating such equipment into your workflow might be a worthwhile consideration.Specialized Assembly Platforms

To maintain the flatness and consistency of each letter during assembly, using a specialized assembly platform can be beneficial. These platforms provide a stable working surface, reducing the risk of errors due to uneven or shaky surfaces.

Conclusion

Creating big size channel letters requires careful planning and collaboration across multiple stages. By focusing on design, selecting the right materials, and utilizing modern tools such as CNC cutting machines and automatic channel letter benders, you can ensure the quality and effectiveness of your final product. Each project comes with its unique demands, and combining traditional craftsmanship with modern equipment often leads to the best outcomes. If you’re seeking to enhance efficiency and precision in your production process, considering these tools could be a valuable step forward.

Learn more about

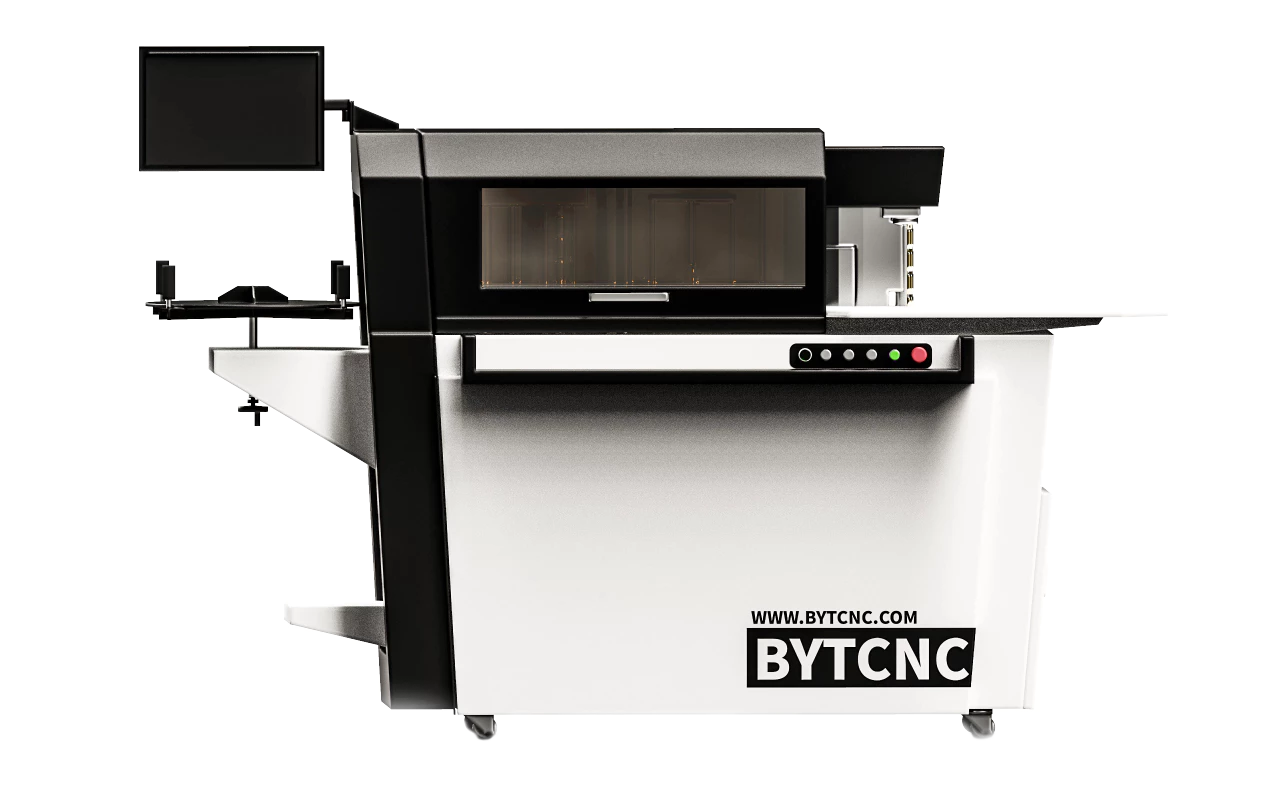

BYT Channel Letter Bender

Processing material width:10-160mm

Thickness:

Aluminum 0.3-1.5mm,

Stainless steel 0.3-1.2mm.

Suitable for All kinds of material.