How to Save Money on Making Channel Letters

In today’s competitive signage industry, finding ways to reduce costs without compromising quality is essential. Whether you’re a small shop or a large-scale producer, maximizing your budget can make a big difference in your profitability. In this article, we’ll start with some general money-saving tips for producing channel letters and then delve into how using an automatic channel letter bender can transform your operations and lead to even greater savings.

General Money-Saving Tips for Channel Letter Production

Before we dive into the specifics of automatic channel letter benders, let’s explore a few basic strategies that can help you save money across the board in channel letter production:

Bulk Purchasing of Materials

- Why It Saves Money: Buying materials like aluminum, acrylic, and LED lights in bulk can significantly reduce your per-unit costs. Suppliers often offer discounts for large orders, which can translate into considerable savings, especially if you produce letters regularly.

- How to Implement: Plan your projects to anticipate material needs. Establish relationships with reliable suppliers who can offer bulk discounts.

Streamline Your Design Process

- Why It Saves Money: The design phase can be time-consuming, and revisions add costs. Streamlining this process using design software that integrates directly with your production equipment can reduce errors and shorten production time.

- How to Implement: Invest in software that allows easy adjustments and quick conversion to production-ready files, reducing the need for multiple revisions.

Optimize Material Usage

- Why It Saves Money: Wastage during cutting and bending can increase material costs. By optimizing how materials are cut and used, you can reduce scrap and make the most out of your purchases.

- How to Implement: Use design software to calculate the best layout for cutting materials, ensuring minimal waste.

Invest in Energy-Efficient Equipment

- Why It Saves Money: Equipment that consumes less energy can significantly lower your utility bills, especially if you run a large operation.

- How to Implement: Research and choose machines that are energy-efficient and designed for long-term use. Look for equipment with Energy Star ratings or other energy efficiency certifications.

Why an Automatic Channel Letter Bender is a Game-Changer

After implementing the basic money-saving strategies, consider the impact of upgrading your equipment, particularly by using an automatic channel letter bender. Here’s how it can further enhance your cost-saving efforts:

1. Drastic Reduction in Manpower Costs

One of the most significant expenses in channel letter production is labor. Manual processes require a skilled workforce, which can be expensive.

- Cost Savings: With an automatic channel letter bender, you can reduce the number of employees needed to operate the machinery. The machine handles cutting, bending, and shaping, tasks that would typically require multiple workers. This reduction in workforce needs can save you thousands in salaries, benefits, and overtime pay.

- Implementation: Shift your workforce from manual production to machine operation, focusing on training a smaller, highly skilled team to operate and maintain the bender.

2. Enhanced Production Efficiency

Time is money, and the faster you can produce high-quality channel letters, the more projects you can take on.

- Cost Savings: An automatic channel letter bender speeds up production by automating repetitive tasks. It works faster than manual labor and can run continuously without breaks, reducing the time required to complete orders. This efficiency allows you to increase output without hiring additional staff.

- Implementation: Integrate the bender into your production line to handle large volumes of work with consistent quality, reducing lead times and increasing customer satisfaction.

3. Material Optimization and Waste Reduction

Materials like aluminum and stainless steel are a significant cost in channel letter production. Any waste directly impacts your bottom line.

- Cost Savings: The precision of an automatic bender ensures that materials are cut and bent with minimal waste. Unlike manual methods, which can result in errors and wasted materials, the bender’s accuracy optimizes material usage, leading to lower material costs.

- Implementation: Use the bender’s software to plan cuts and bends meticulously, ensuring each piece of material is used to its fullest potential.

4. Lower Maintenance and Operational Costs

Manual machines often require frequent maintenance, which can disrupt production and increase costs.

- Cost Savings: Automatic channel letter benders are designed for durability and typically have lower maintenance needs. This translates into fewer interruptions and reduced spending on repairs. Additionally, because these machines are more energy-efficient, you’ll also save on utility costs.

- Implementation: Schedule regular maintenance checks to keep the bender in optimal condition while enjoying reduced downtime compared to manual machines.

5. Flexibility and Versatility in Production

Adapting to different customer needs can be challenging with manual equipment, which might not handle a wide range of materials or designs.

- Cost Savings: An automatic channel letter bender can work with various materials and create complex designs, eliminating the need for multiple machines or outsourcing. This flexibility allows you to take on diverse projects without additional investment in new equipment.

- Implementation: Train your team to utilize the bender for a range of projects, maximizing the return on your investment and reducing the need for extra tools or machines.

Conclusion: Maximize Your Savings with Smart Investments

While basic cost-saving measures can help you reduce expenses in channel letter production, the savings come from investing in advanced technology like an automatic channel letter bender. By cutting down on labor, improving efficiency, reducing waste, and lowering operational costs, this equipment pays for itself over time and helps your business stay competitive in a crowded market.

Implement these strategies today to start seeing significant savings in your channel letter production process and consider the long-term benefits of upgrading to an automatic channel letter bender. Your bottom line will thank you!

Learn more about

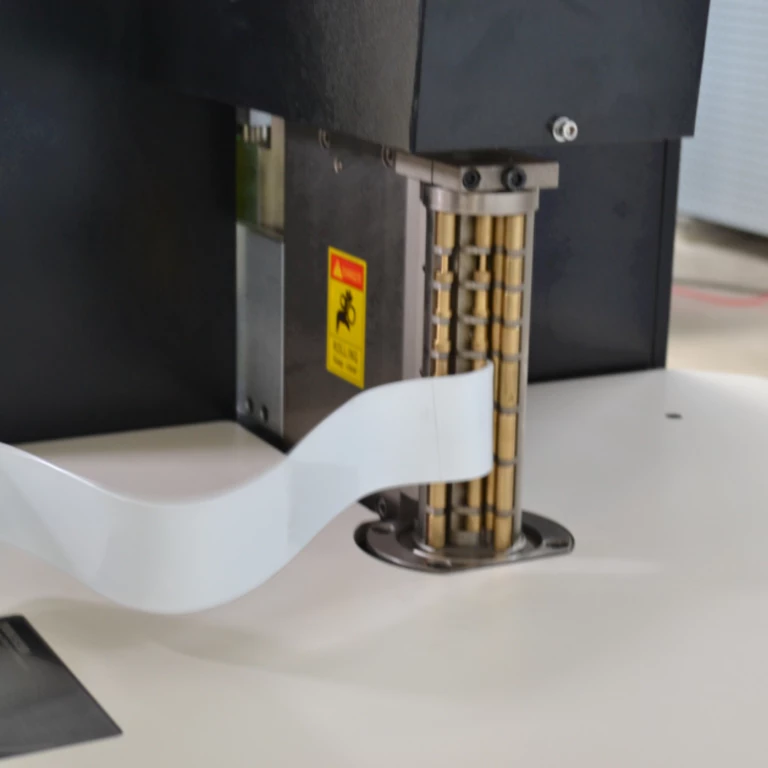

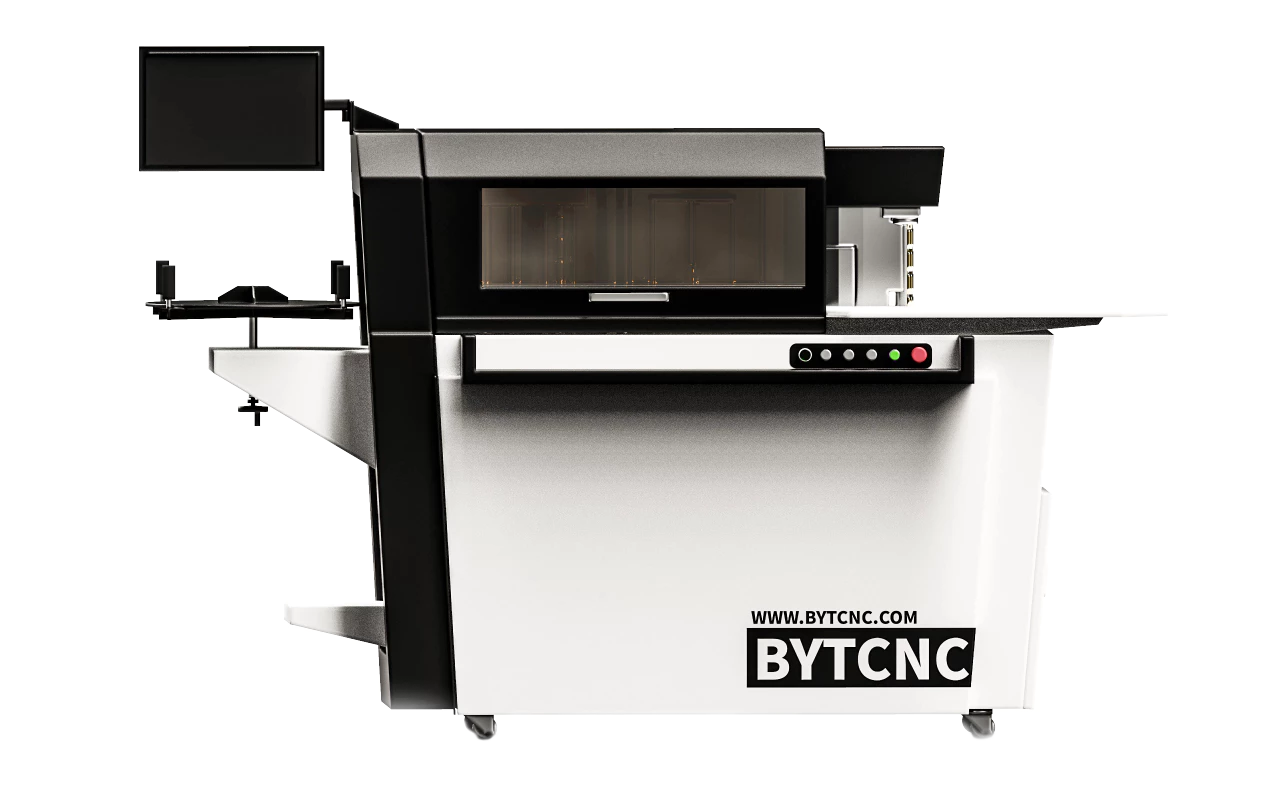

BYT Channel Letter Bender

Processing material width:10-160mm

Thickness:

Aluminum 0.3-1.5mm,

Stainless steel 0.3-1.2mm.

Suitable for All kinds of material.

SITE INFO

Sign Machine Manufacturer Since 1996

@ BYTCNC

Email: [email protected]

WhatsApp: +86 193 5320 6091

WeChat: +86 193 5320 6091

More Contacts